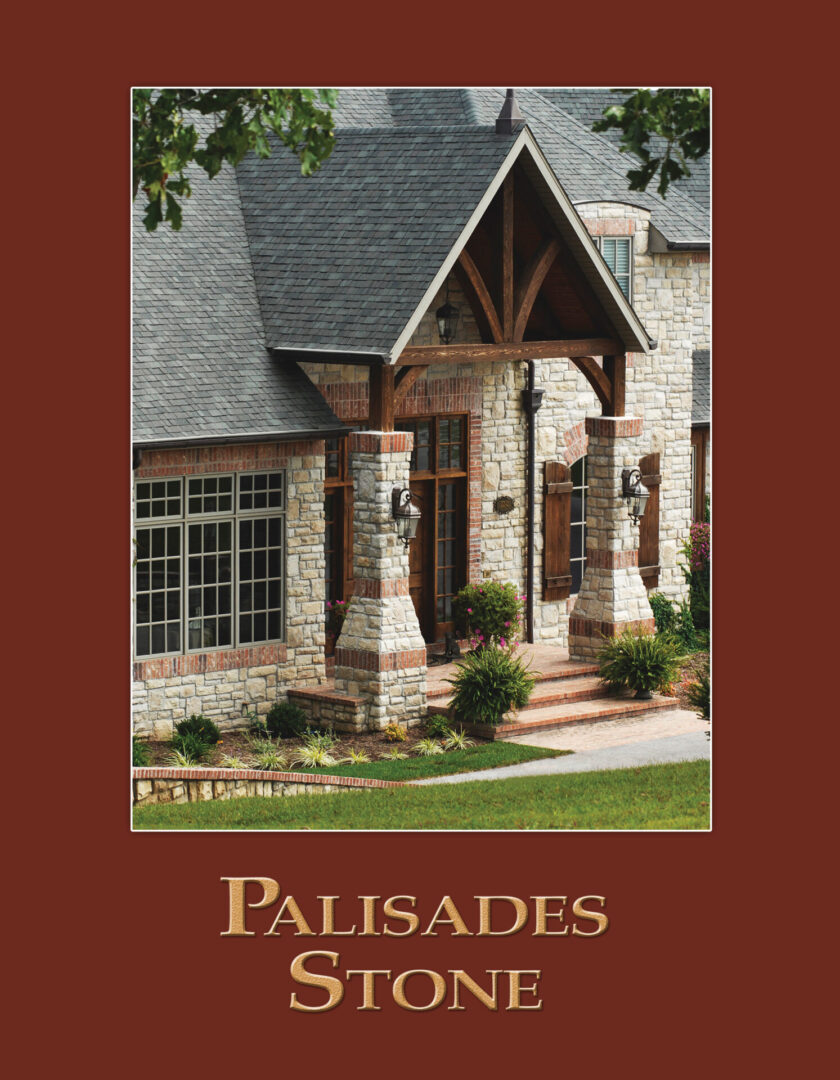

Veneers: Manufactured Stone at Reasonable Price

A Great Aesthetic Choice for Any Property

Elegantly Designed Stone Veneer

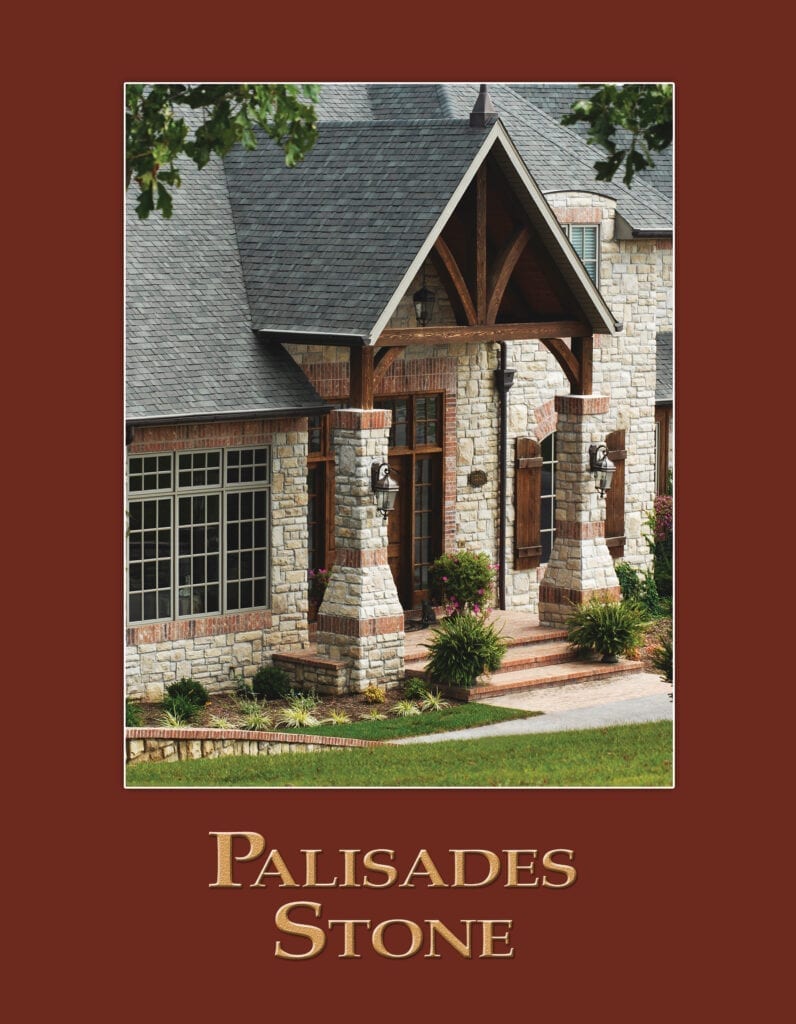

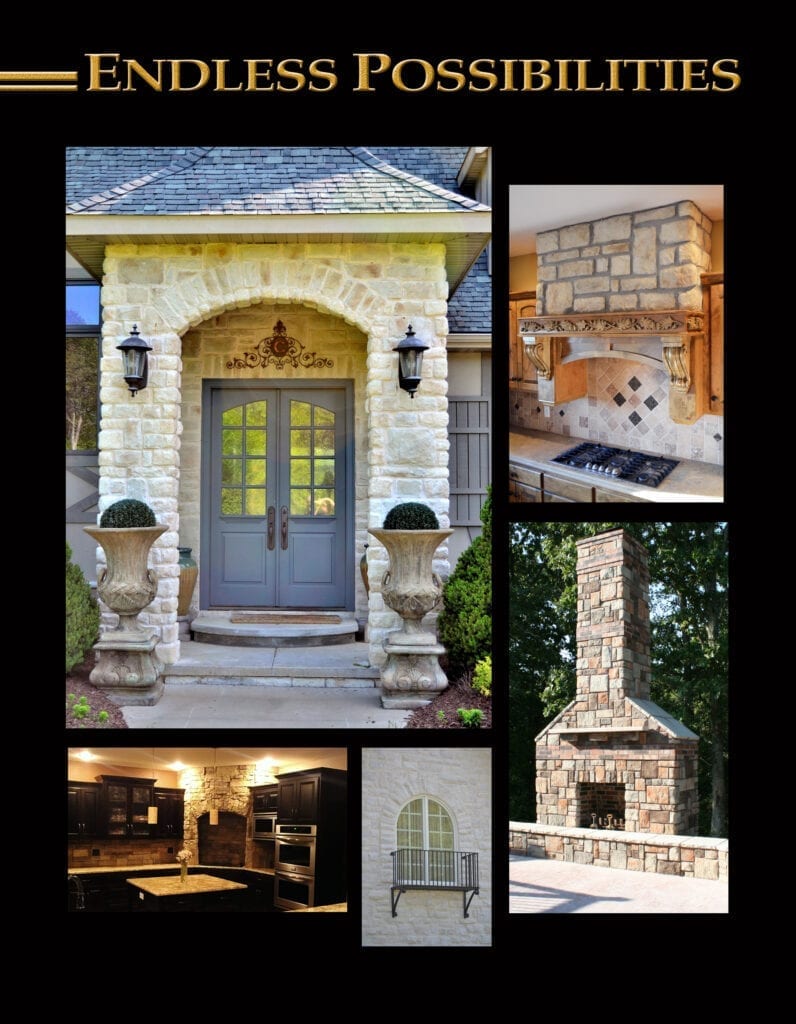

Throughout the centuries, stone has been an enduring symbol of strength, beauty, and elegance. Used in old castles and modern homes, it continues to be a popular choice for almost any build project. Palisades Stone in Springfield, MO recognizes the lasting beauty and rich textures of natural stone and has even improved on it.

Why Use Stone Veneer

“Every block of stone has a statue inside it and it is the task of the sculptor to discover it.”

- Michelangelo

An Uncanny Similarity

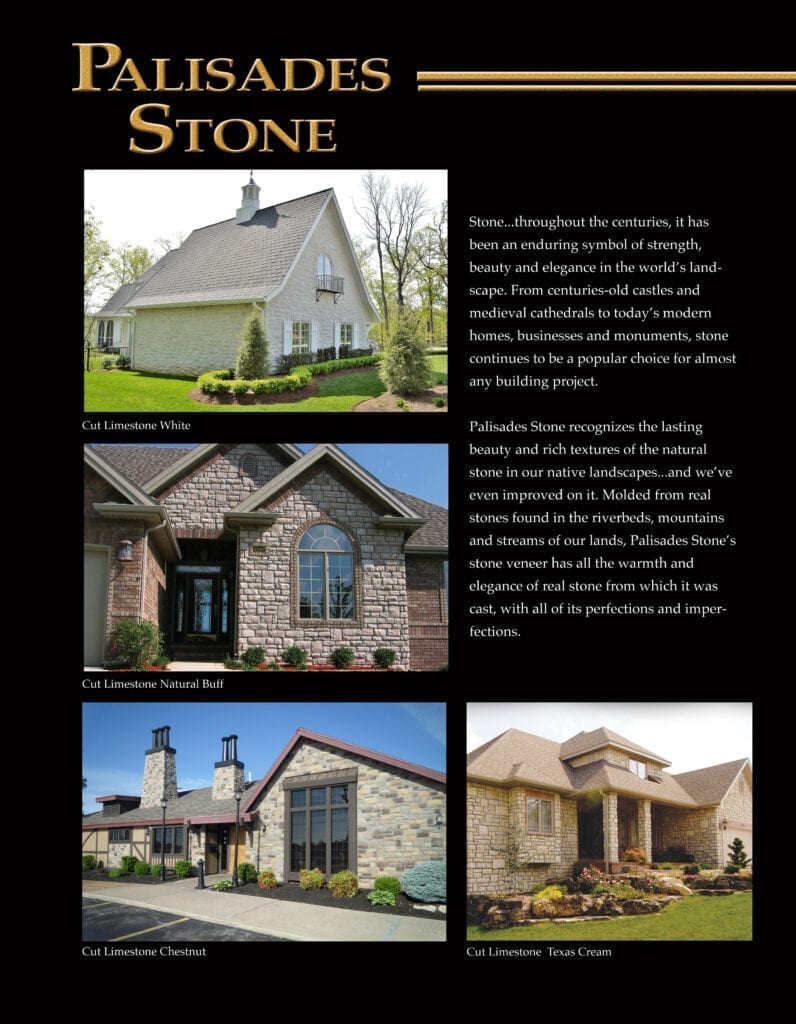

We have perfected the manufacturing process to offer you high-quality veneers made from stones found in riverbeds, mountains, and streams. It is almost impossible to distinguish what we offer from from natural stones &, at a very economical price.

Convenient and Customizable

At Palisades Stone we are located right in Springfield MO with easy pick-up and delivery options. Our stone can be custom made to your exact color and style specifications.

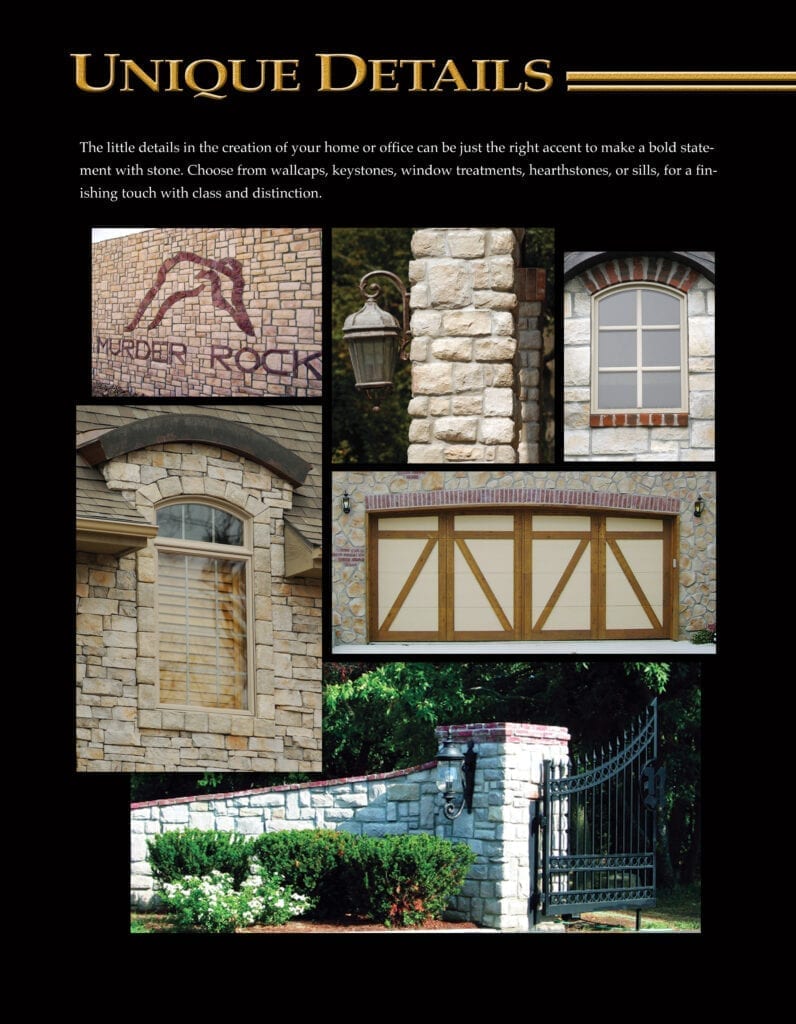

Unique Statement Walls

Even the little details in the construction of your residential property or commercial establishment can make a bold statement. Choose from our vast range of wall caps, keystones, window treatments, hearthstones, and sills.

Quality Products

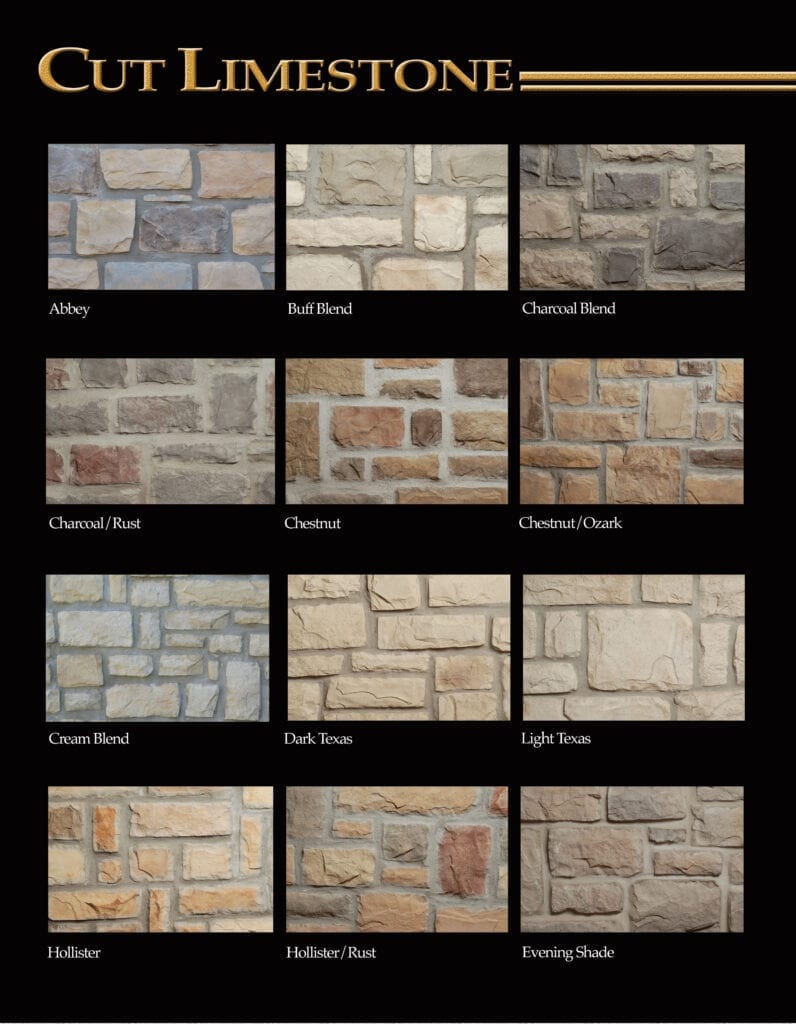

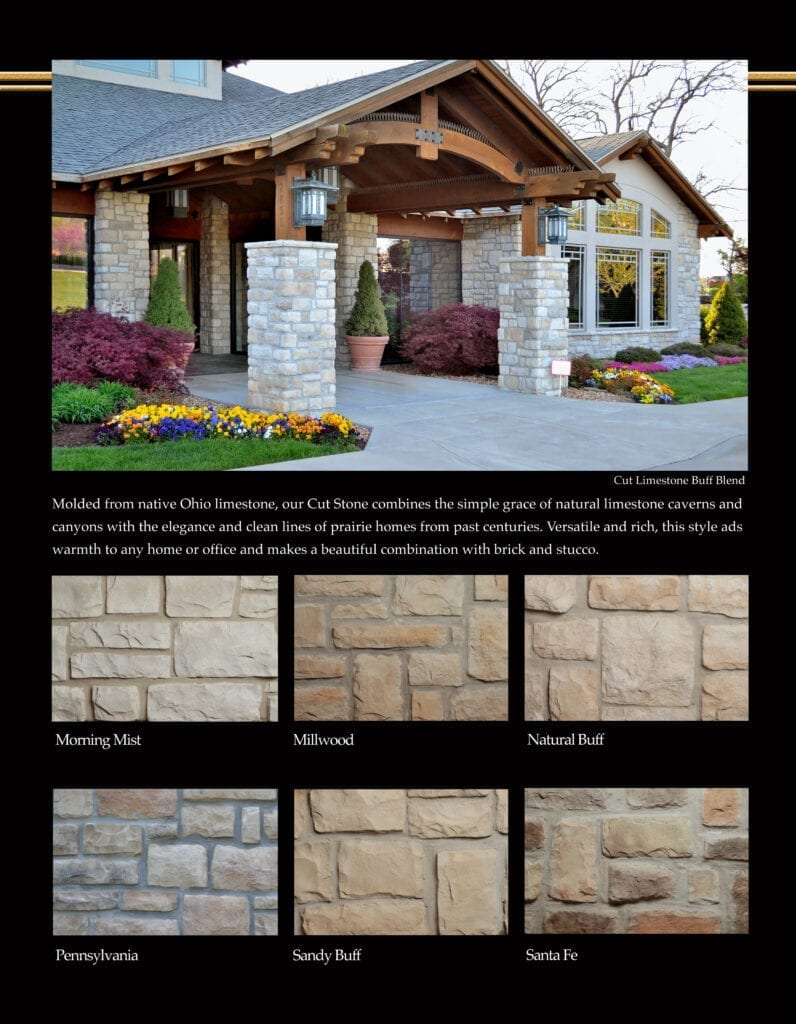

Cut Limestone

We cut Ohio limestone, which we use for our cut stone products. Combine the simple grace of natural limestone caverns with clean lines of prairie homes with our help. Our products offer the finest in versatility and style. They can add depth to any room and make a beautiful combination with brick and stucco.

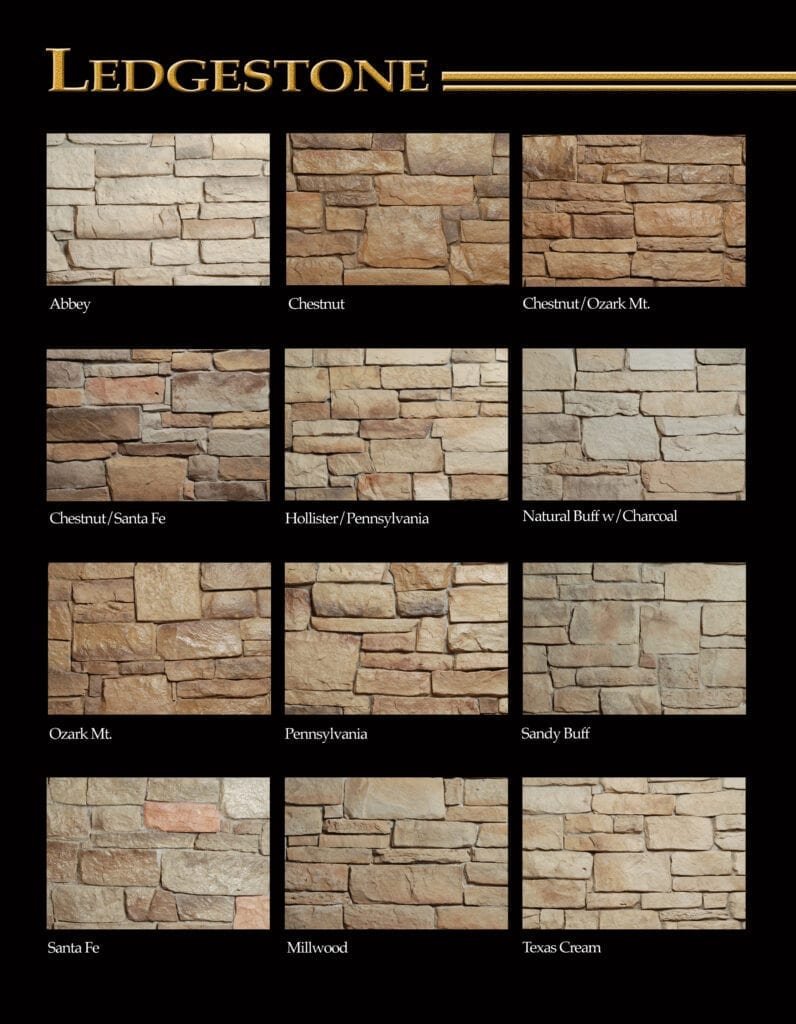

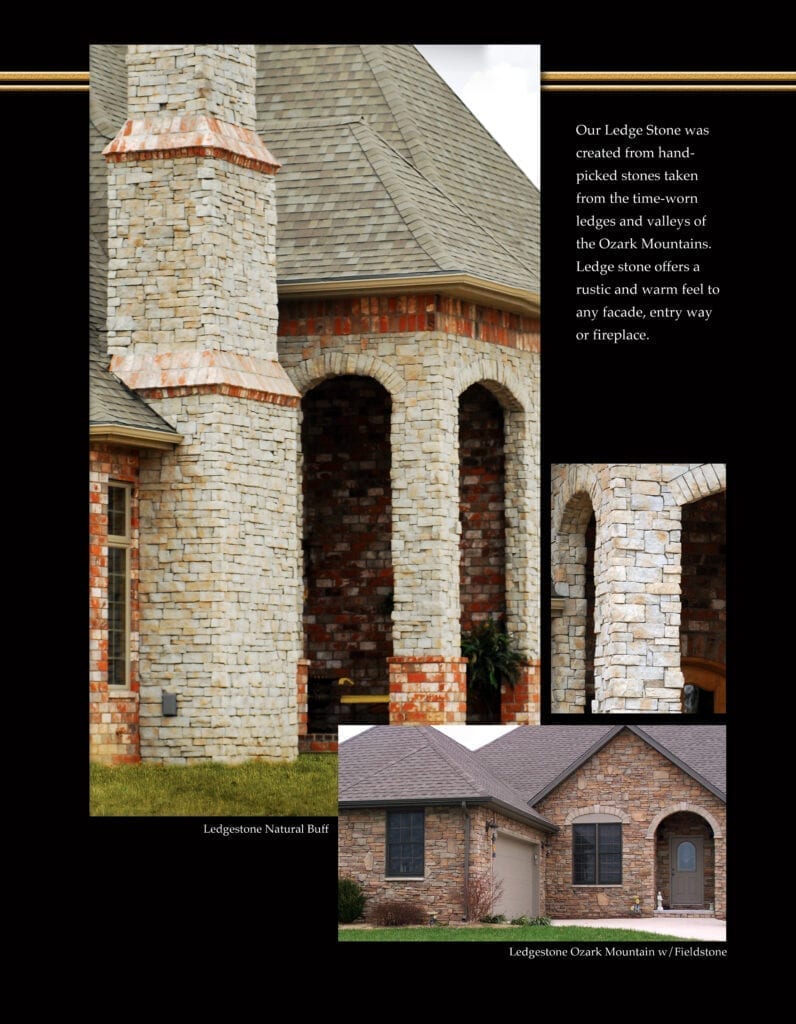

Ledgestone

Our ledgestone is created from handpicked stones taken from the worn ledges of the valleys by the Ozark Mountains. They offer a rustic and warm feel to any façade, entryway, or fireplace.

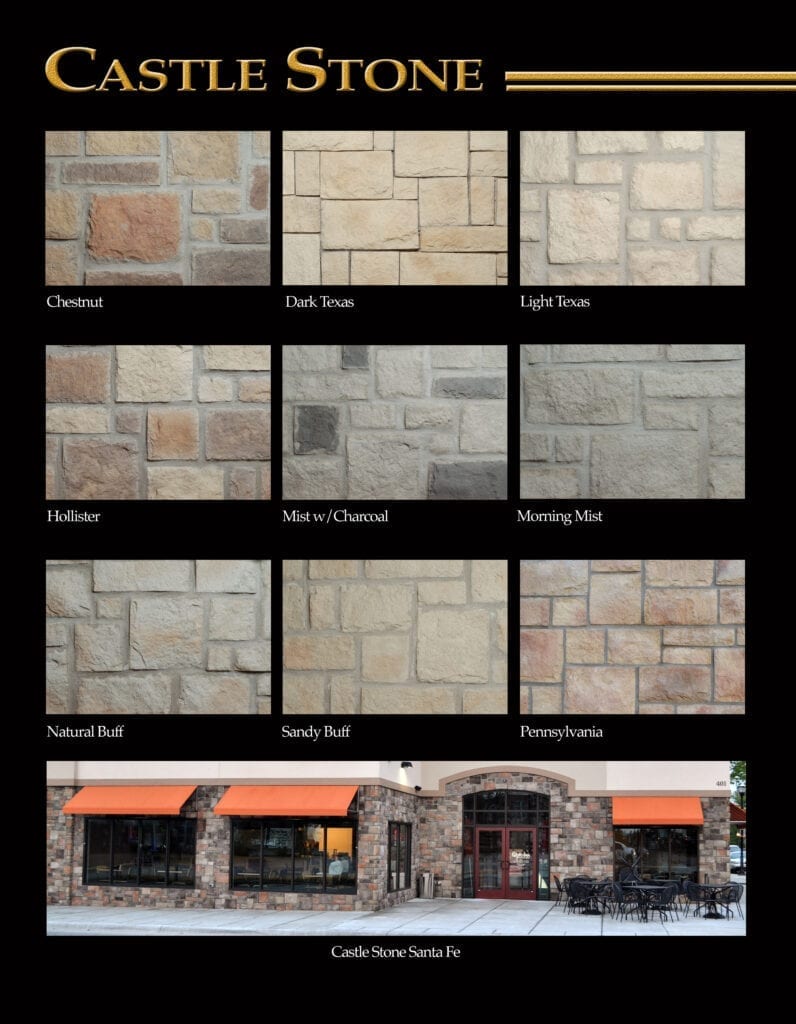

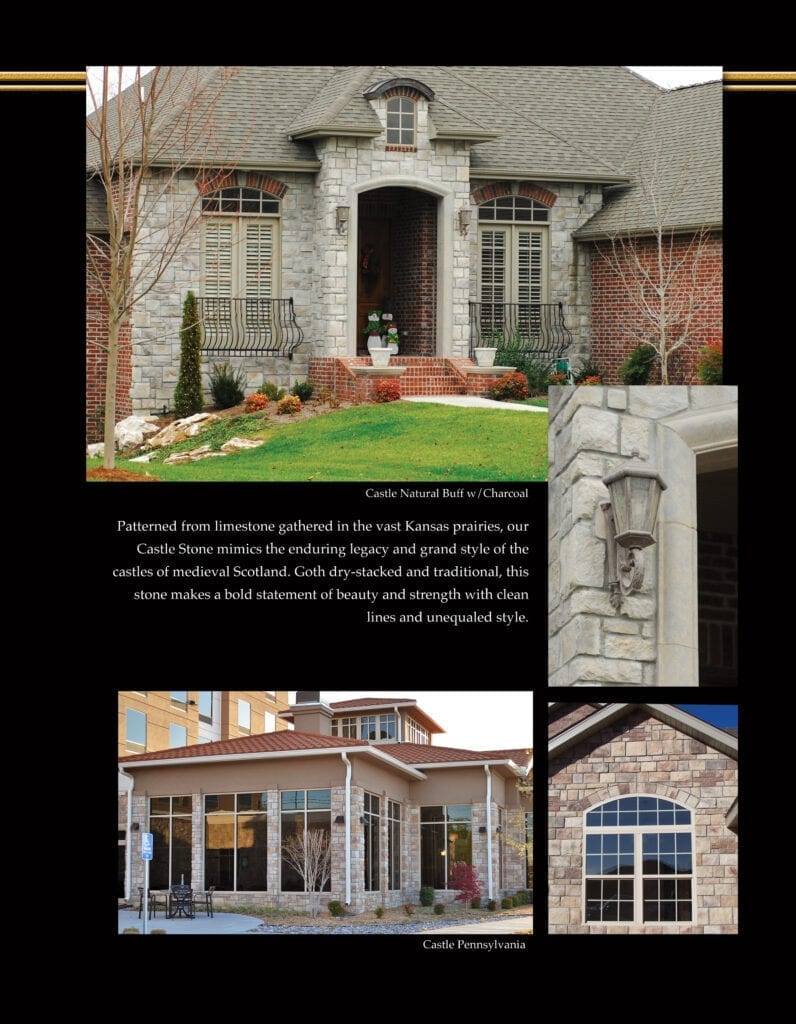

Castle Stone

Patterned from the limestone gathered from Kansas prairies, our castle stone mimics the enduring legacy and grand style of the castles during medieval Scotland. This gothic, dry-stacked, and traditional stone makes a striking statement.

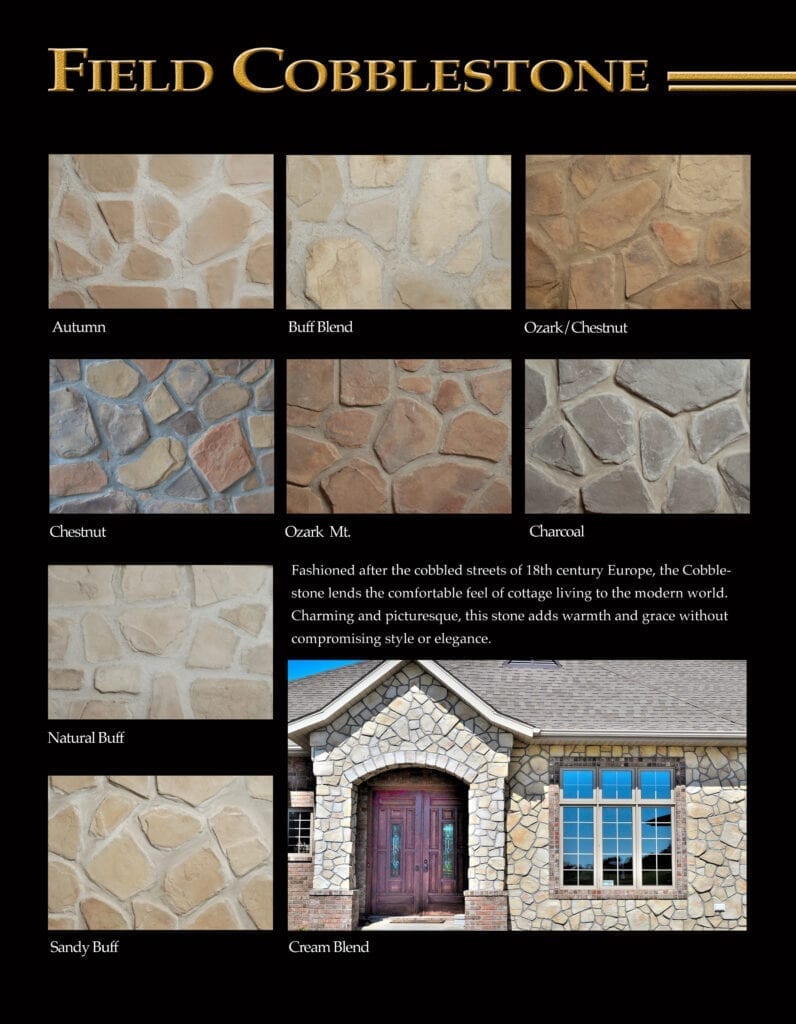

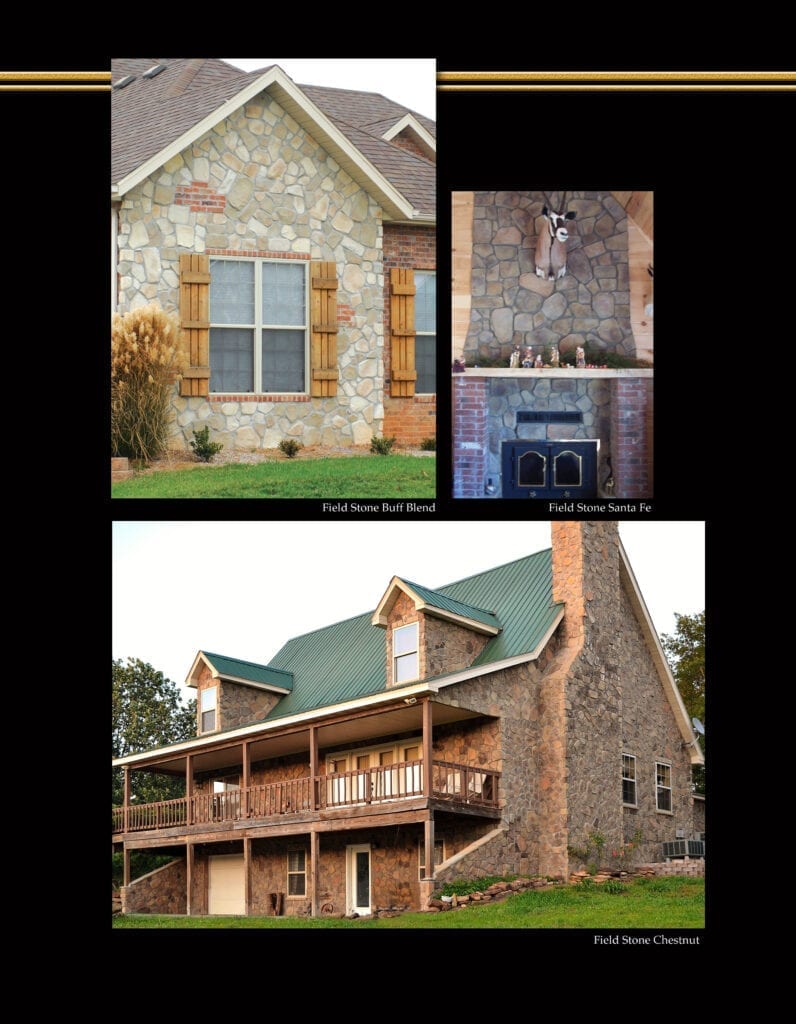

Field Cobblestone

Fashioned after the cobbled streets during eighteenth-century Europe, field cobblestone lends the comfortable feel of living in a cottage to the modern world. This charming, picturesque stone helps add warmth and grace without compromising style or elegance.

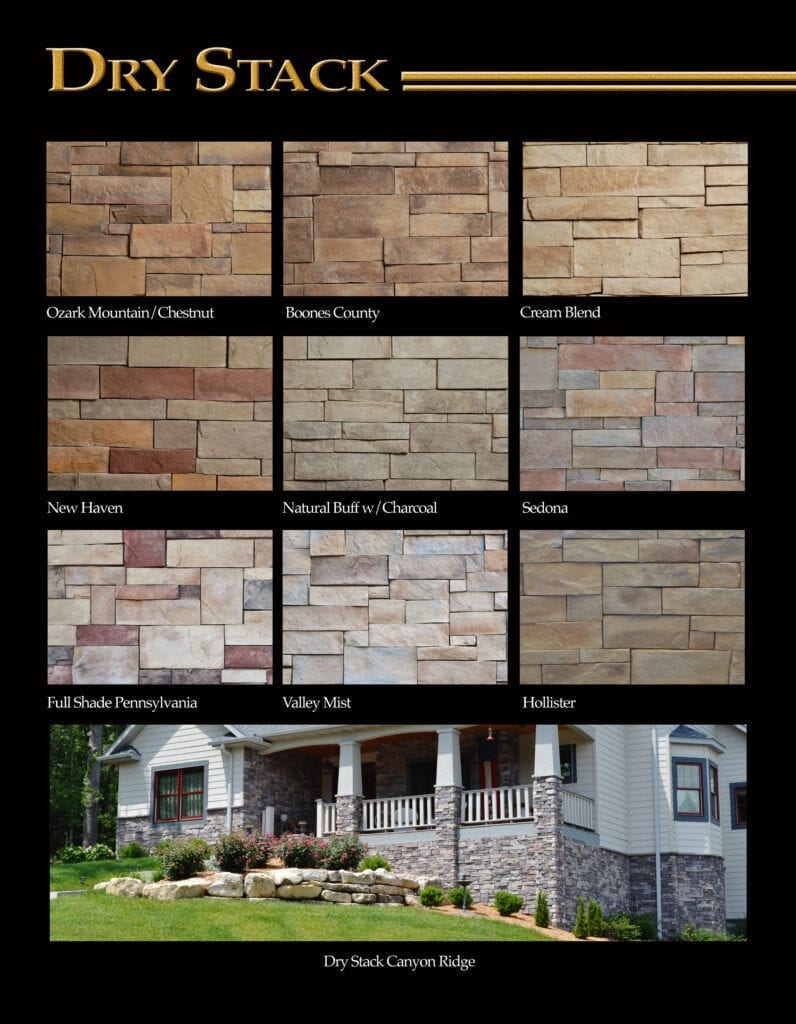

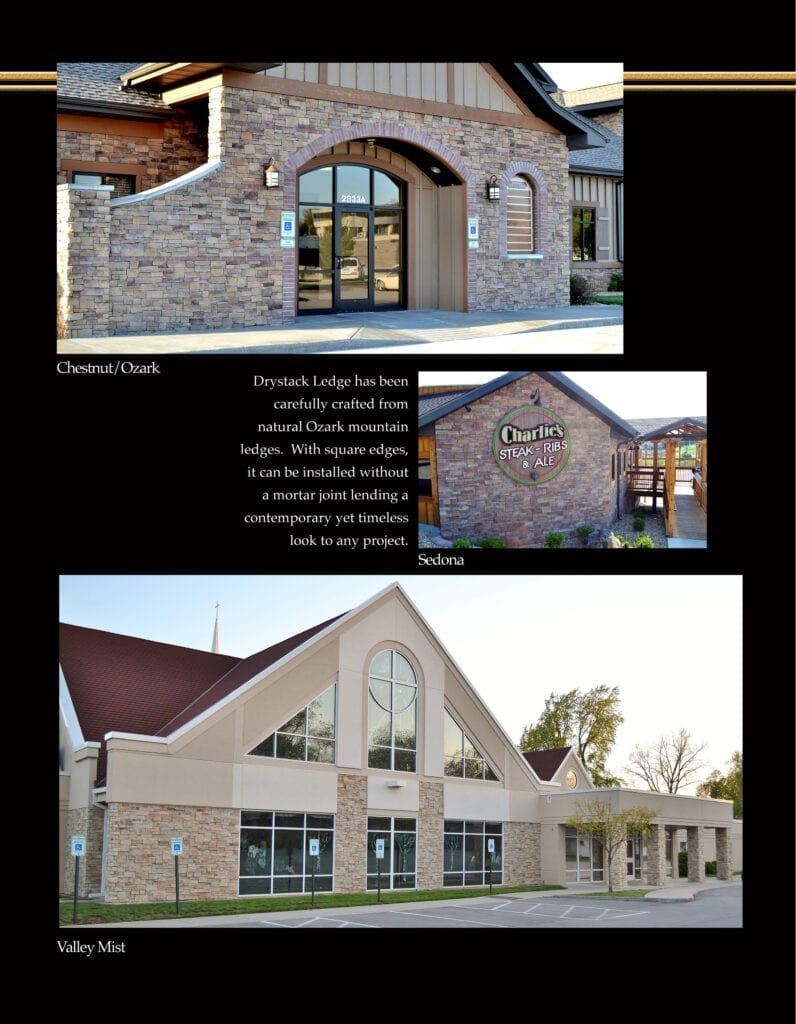

Dry Stack

With square edges, a dry stack can be installed without a mortar joint. Our product was carefully crafted from natural Ozark Mountain ledges. It creates a contemporary yet timeless look in any building project.

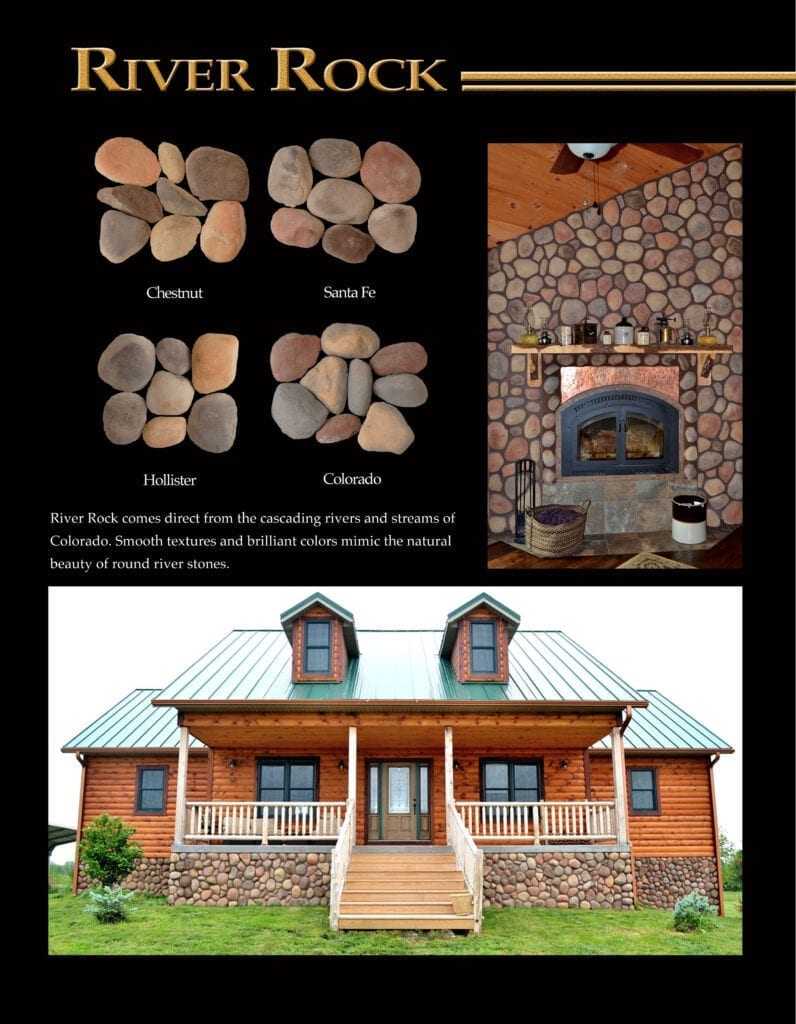

River Rock

Mimicking the natural beauty of round river stones, river rock has a smooth texture and brilliant colors. It comes directly from the cascading rivers and streams of Colorado.

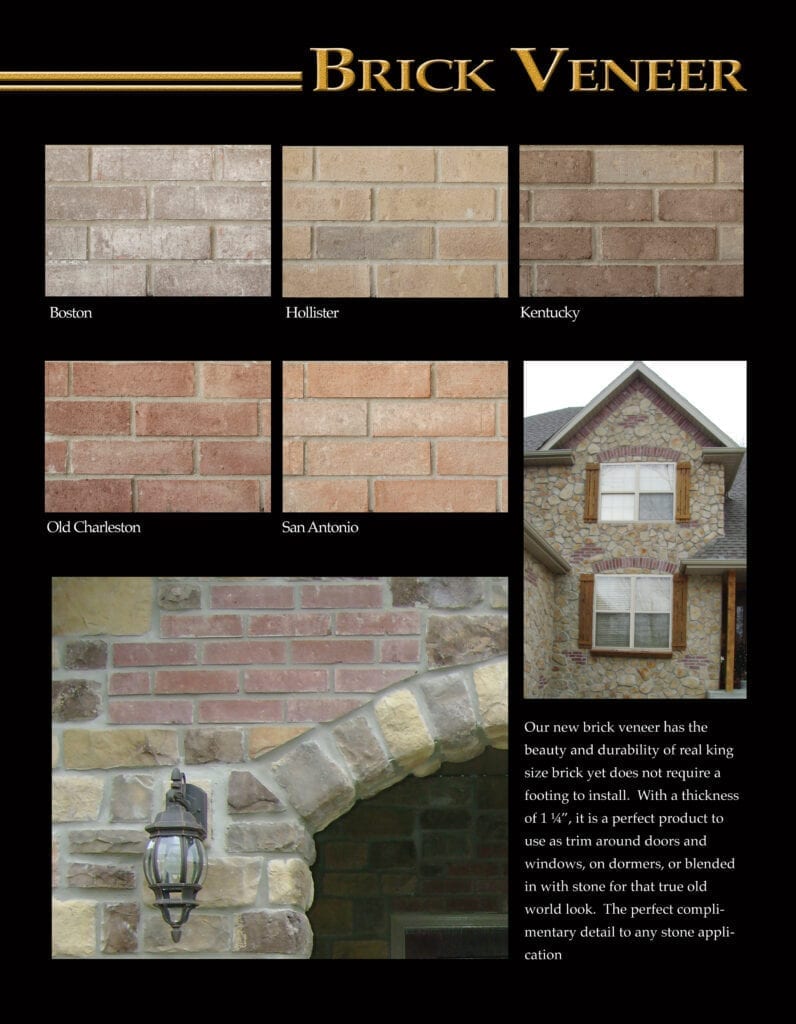

Brick Veneer

Our new brick veneer has the beauty and durability of real king-size bricks. However, it does not require a footing to install. With a thickness of 1' 1/4," it is a perfect product to use as trim around doors and windows. It is also the perfect complementary detail to any stone application.

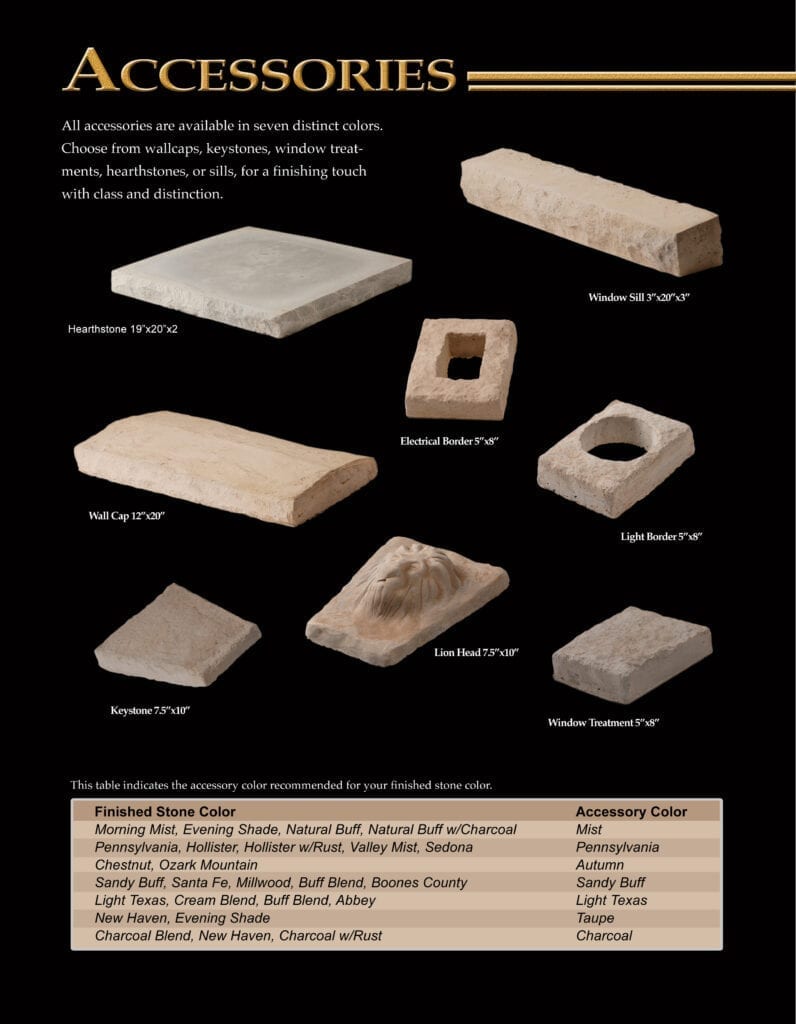

Accessories

All our accessories are available in seven distinct colors. You can choose from wall caps, keystones, window treatments, hearthstones, or sills for a finishing touch with class and distinction.

Warranty Information

- 75-Year Limited Warranty

Our warranty lasts for 75 years. If defects are found when installing our products, we will ensure that these were not caused by improper handling due to noncompliance with local building codes and written instructions.

This warranty excludes deterioration caused by chemicals paints, wall movement, building settlement, and discoloration from oxidization. The coverage is not limited to the original buyer and does not include labor. However, it is restricted to the repair or replacement of the product.

Technical Information

Color Retention: Even after years enduring harsh sun, rain, and other ill effects of the weather, our permanent oxide shading withstands the elements. It does not fade or have any unwanted color change.

Absorption and Compression Strength: We are tested and approved in accordance with the industry standards.

Combustion: Independent testing has proven the durability of our stone, and it has shown that we exceed building requirements.

Installation Instructions

Part 1: General

- References

- ASTM C91: Masonry Cement Specification

- ASTM C150: Portland Cement Specification

- ASTM C207: Hydrated Lime Specification for Masonry Purposes

- ASTM C270: Mortar Specification for Unit Masonry Purposes

- Quality Assurance

- Applicator: We have three years of experience in installing various types of manufactured stone veneers.

- Project Conditions

The following instructions must be followed prior to, during the installation project, and 48 hours after its completion:

- You must maintain your materials in an environment that is a minimum of 40 degrees Fahrenheit.

- Protect the materials from rain and moisture.

- There must not be any construction activity on the opposite side of the wall.

- Warranty

- See attached limited warranty.

Part 2: Products

-

Mortar

-

Masonry Sand

-

Portland Cement (ASTM C150)

-

Type I for Masonry Cement Type N (ASTM C91)

-

-

Masonry Sealer: Non-Film Forming Sealer

-

Weather-Resistant Barrier

-

Metal Lath: 18-Gauge Galvanized Woven Wire Mesh

Part 3: Execution

-

Preparation

-

Open Stud: Install paperbacked metal lath to studs using galvanized nails or staples, which penetrate a minimum of 1" and 4" on center. Apply 3/8" to 1/2" scratch coat and allow it to dry for 48 hours. Wrap the weather-resistant barrier and metal lath with a minimum of 16" around its outside and inside corners.

-

Sheathed Surfaces: Install one layer of weather-resistant barrier with lap joints in a four-inch shingle fashion. Apply code-approved metal lath, and attach it with galvanized nails or staples which penetrate a minimum of one inch. Apply six inches on the center vertically and horizontally. Wrap the weather-resistant barrier and metal lath with a minimum of 16" around its outside and inside corners.

-

New, Clean, and Untreated Concrete and Masonry Surfaces: Examine newly poured concrete closely to ensure that its finished surface contains no releasing agents. If it does contain form oil or release agents, etch the surface with muriatic acid, rinse and/or score with a wire brush, or use high-pressure water or sandblasting device to remove.

-

Existing Concrete and Masonry Surfaces: If it is required, you can remove the paint, coatings, sealers, and dirt.

-

-

Mortar Mixing

-

Thoroughly mix the mortar ingredients in quantities needed for immediate use in accordance with ASTM C270, Type N.

-

Do not use antifreeze compounds to lower the freezing point of mortar.

-

-

Application

-

Apply 3/8" to 1/2" of mortar to the lath, dampened masonry, stucco, or concrete surface. Make sure that it’s covering roughly 10 square feet.

-

Butter the back of each stone unit completely with mortar before pressing the units firmly into position on the soft mortar bed.

-

Wiggle and apply slight pressure to the unit to ensure firm bonding, which may cause the mortar to extrude slightly.

-

Place units with uniform mortar joints. Stone joints should not be over ½” in width.

-

Remove excess mortar and do not allow it to set up on the face of units.

-

Rake and tool the joint before the mortar sets.

-

Clean and finish the joints.

-